Cultivating trust with useful, accurate and secure advice on cleaning thermal printer heads. Descriptive headings clearly organize content.

Thermal printers use heat to transfer ink onto paper. Over time, residue builds up on the printhead, reducing print quality. Cleaning removes residue so your printer works properly.

Follow these steps to safely clean the printhead:

Gather Materials

- Isopropyl alcohol (70% or higher)

- Cotton pads or swabs

- Distilled water

- Lint-free cloth

Avoid using materials that could scratch the printhead.

Power Off and Open Printer

- Turn off and unplug the printer

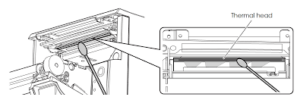

- Open the cover to access the printhead

- Remove ribbon or label roll if needed

With the cover open, locate the printhead. It may be under a bar or protector.

Inspect and Remove Debris

- Use a flashlight to inspect the printhead for residue or debris

- Carefully wipe away any lint or debris with a lint-free cloth

- Do not scratch or touch any electrical contacts

Be gentle so you don’t accidentally damage any printer parts.

Apply Isopropyl Alcohol

- Dip the cotton pad or swab in isopropyl alcohol

- Gently wipe the printhead in a back-and-forth motion along the ridges

- Apply more alcohol as needed to remove residue

Apply only light pressure when cleaning to avoid damaging the printhead.

Rinse and Dry

- Dip a new cotton pad in distilled water

- Wipe the printhead to rinse off remaining residue and alcohol

- Allow the printhead to fully air dry

Proper drying prevents issues like paper jams when you resume printing.

Reassemble and Test

- Reinstall any parts removed earlier

- Close the printer and plug it back in

- Turn on the printer and run a test page

Examine the test page for any missing spots or lines indicating clogged or dirty print elements. Re-clean if needed.

Troubleshooting Tips

- If residue remains, repeat cleaning focusing on problem areas

- For stubborn debris, let alcohol soak for 30-60 seconds before wiping

- Check and adjust printhead pressure springs if having print quality issues

Avoid excessive wiping or soaking, which can damage the printhead.

Key Takeaways

- Use isopropyl alcohol and cotton swabs to dissolve and remove residue

- Gently wipe in a back-and-forth motion along printhead ridges

- Power off the printer and allow printhead to fully dry before testing

- Improper cleaning can scratch or damage the delicate printhead

Regular cleaning maintains good print quality and extends the printer’s lifespan.

Conclusion

Cleaning a thermal print head prevents issues like reduced print quality, streaks, and clogs. Follow the steps properly using gentle pressure and the correct cleaning solutions so you don’t accidentally damage the printhead.

Test print quality after cleaning. Repeated cleanings may indicate other printer issues needing service. With proper maintenance, a thermal printer should provide years of quality printing.

Frequently Asked Questions

- What are signs the printhead needs cleaning?

Signs include faded prints, streaks, lines, or dots missing from output. These indicate debris or residue on the printhead. - How often should you clean the printhead?

General guidance is to clean the printhead every 1-3 months. Clean more frequently if you notice print quality declining. - What percentage of isopropyl alcohol should be used?

70% or higher isopropyl alcohol works best since it readily dissolves residue. Higher than 90% alcohol evaporates too quickly to dissolve debris effectively. - Can I use rubbing alcohol?

Yes, typical rubbing alcohol contains 70% isopropyl alcohol so it is safe for printhead cleaning. - What happens if you touch the printhead contacts?

Skin oils and moisture can corrode the contacts, eventually causing connectivity failures. Avoid direct contact with electrical connectors. - How do you clean a clogged thermal printhead?

Submerge a cotton pad in isopropyl alcohol, place it on the clogged section and let it soak for 30 to 60 seconds before gently wiping the area. Repeat as needed. - Why does the thermal printhead get dirty?

Heat melts printer ink or ribbon residue which sticks to the printhead as it cools. Environmental dust also accumulates over time. - Should thermal print head be cleaned when replacing paper roll?

Yes, each paper or label roll replacement creates a good opportunity to inspect and clean the printhead. - Can you use acetone to clean a thermal printer head?

No, acetone is too harsh and could damage protective printhead coatings. Stick with 70% isopropyl alcohol as a milder, safer solution. - How can you avoid getting the thermal printhead dirty?

Use quality ribbons and media designed for your printer model. Store printers covered in a clean environment to reduce dust deposits. - What happens if the thermal printhead is not cleaned properly?

Improper cleaning like excessive wiping or using harmful chemicals can scratch or damage the printhead, requiring replacement. - Can thermal printhead be cleaned with water?

Water alone won’t dissolve residue. Use isopropyl alcohol to cut grease and grime. Follow with distilled water to prevent mineral deposits. - How do you unclog a thermal printhead?

Soak cotton pad with alcohol. Hold against printhead for 30-60 seconds. Wipe back-and-forth along ridges. Repeat process until clear. - Why does my printer print faded lines?

Fading is typically caused by dirt, dust, adhesive buildup or other debris on printhead components, requiring cleaning. - How do you maintain a thermal printer?

Printhead cleaning, using quality media designed for the printer model, storing covered when not in use, and having annual service checks done. - Does thermal printer require ribbon?

Direct thermal printers print directly onto chemically coated heat-sensitive media so they do not require separate ink ribbons. - What are thermal print heads made of?

Common materials include glazed ceramic for mechanical durability, resistors, electrodes and protective coatings. They withstand high heat while printing.